Easy to use.

Easy to apply.

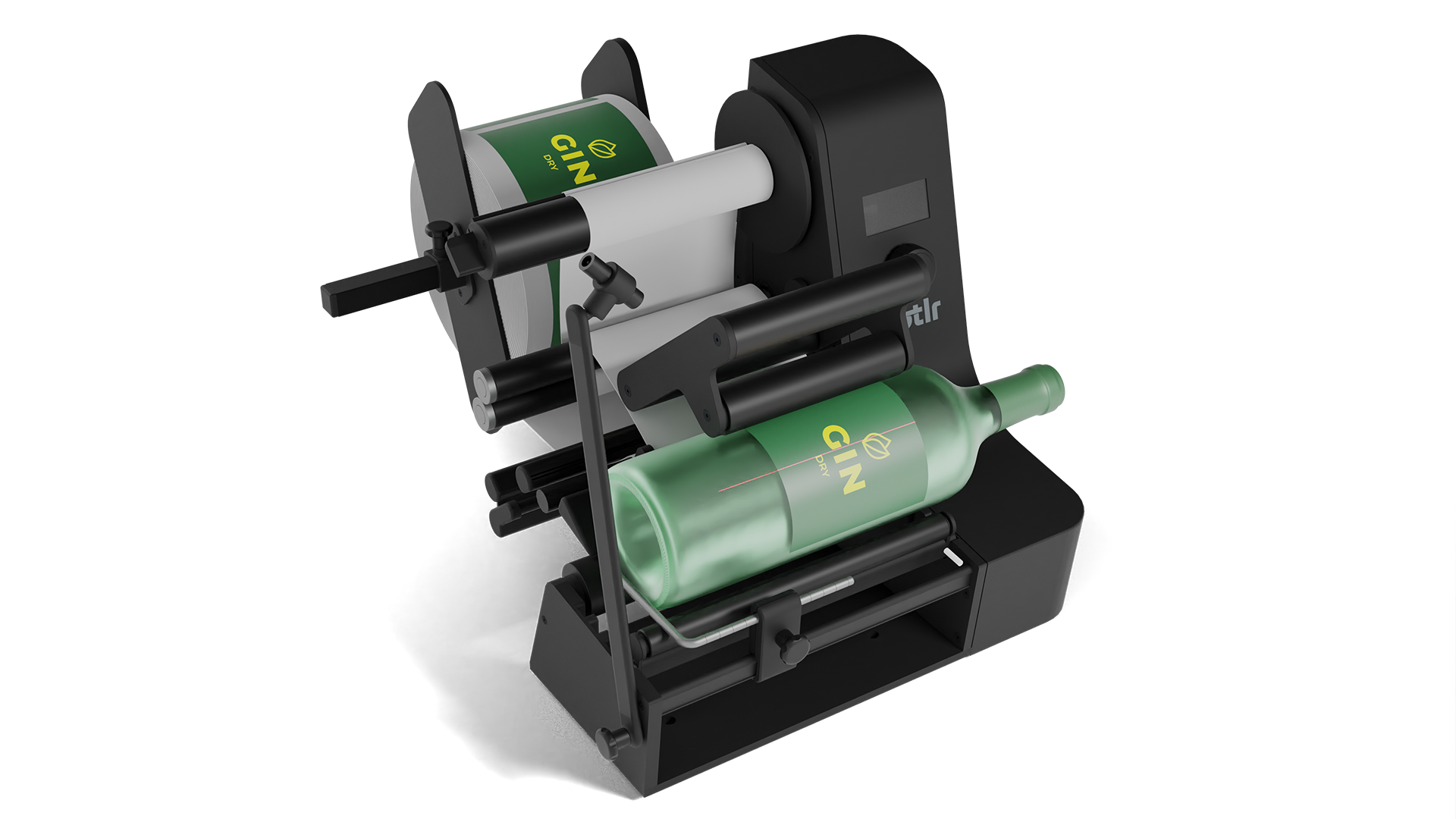

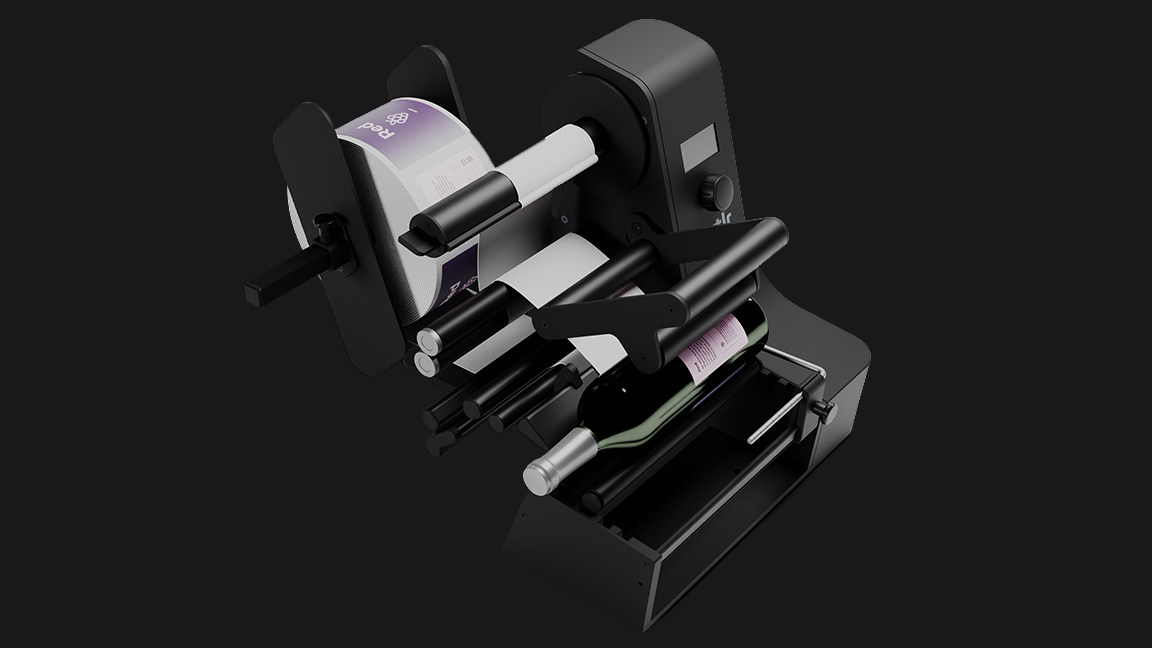

Botlr stands for a variety of technological advancements. The machine itself is not only astounding in its looks; it also makes your job easier. The patented technology measures the bottle diameter and automatically calculates where to place the first and second labels. You can apply them precisely 180° opposing each other or in any desired place. Stop wasting time labeling your bottles manually. It is time to evolve, time to let Botlr work for you.

Benefits

Patented technology automatically measures your bottle’s diameter

Botlr provides you with instructions to position your bottle perfectly. Based on a mark or notch in your bottle, he knows where to start applying your labels. He calculates the bottle diameter and makes sure the position of the 2nd label is precisely 180° opposite to the first or on any other desired place on your bottle.

Intelligent engineering complies with your most demanding applications

Botlr can handle any bottle or container ranging from 13mm to 120mm in diameter without any length restrictions. By rewinding your backing paper, he keeps your workspace clean and safe. The change-over to other labels and different bottle sizes takes less than 2 minutes.

Any size, any shape, any material

Transparent labels, one or two labels, a second label with different dimensions on the same label roll, two labels with a different gap-size and labels in special shapes and thicknesses. Botlr does it all. And he only needs a maximum of 3 labels to calibrate and memorize your label size(s).

Unique connectivity with printer IO interface

A communication stream from Botlr to the IO interface of your color inkjet printer or thermal transfer printer allows you to create a unique print & apply station within your budget.

The patented technology

Botlr’s patented technology ensures perfect label positioning from the first label until the last. Its capacity to automatically calculate the position of the second label makes him one of a kind. You can apply your second label precisely 180° opposite to the first or on any other desired place on your bottle.

Position your labels perfectly, even with a broader sealing cover.

Botlr’s OLED-Screen displays instructions to ensure the best setup for your application. The icons guide you during your configuration. Set your counting goal efficiently to acquire an accurate job status during your process. The integrated sensors provide a live response when required.

It only takes one button to navigate the menu and define settings. Easy, right?

“What I like most is that I can adjust my Botlr according to the specific needs of different bottle types. I can easily apply my labels on any desired place, regardless of their shape and size.”

– Tom, Gin brewer

Botlr-family member since 2022

Already convinced of Botlr’s assistance?

If not, make sure to keep reading.

Advanced media handling

Botlr is unbeatable when it comes to user-friendliness. The Unique Label Sensor Technology ensures impeccable results, even with your most demanding labeling requirements.

Botlr handles one or two labels, transparent labels, a second label with different dimensions on the same label roll, two stickers with different gap-size and labels with extraordinary shapes and thicknesses. That is unparalleled. Other than that, Botlr supports label rolls up to 300mm in diameter and collects the backing material, making your work so much more efficient.

Label up to 1.400 bottles

an hour

Wide OLED Screen

Botlr’s wide OLED-Screen shows you easy-to-use icons. You choose to apply one or two labels, your preferred speed, some counter-preset goals, and so on.

Although Botlr is not a real robot butler, he does have the ability to communicate with the IO interface from barcode printers and color-inkjet printers.